Installation Guide

Painting

Recommended specification for painting pre-primed Bodyguard products.

The use of colors with a Light Reflectance Value (LRV) of 45 or more is recommended, as these lighter colors reflect significantly more heat. Testing has shown that dark colors can generate temperatures in excess of 185℉.

This level of heat can reduce the life of the paint film and cause cracks to appear in the timber surface. In direct sunlight, light colors under the same conditions can be as much as 95℉ cooler. (LRV of white is 95-100, LRV of black is 0-5).

Bodyguard is supplied pre-primed and undercoated (double coated) and we recommend the following:

Bodyguard is supplied pre-primed (double coated) and the following is recommended.

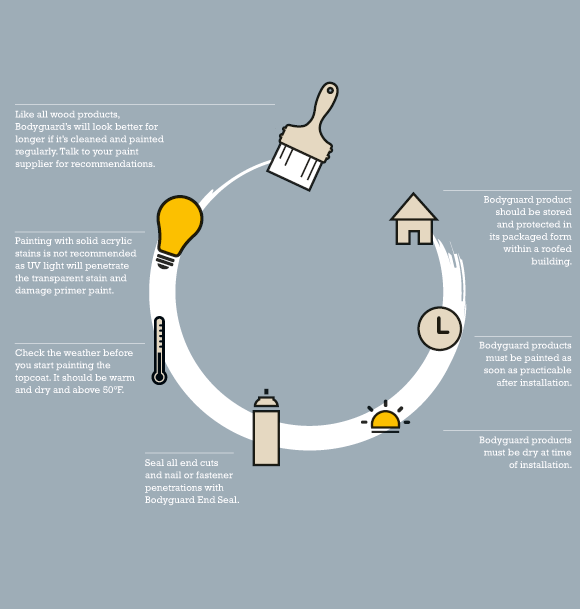

- Bodyguard products must be painted as soon as practicable after installation.

- Bodyguard products must be dry before commencing painting (a moisture content of 15% or less).

- Apply the topcoat in warm, dry weather not below 50°F.

- Painting with solid acrylic stains is not recommended as UV light will penetrate the transparent stain and damage the primer paint.

The painter or painting contractor should check the Bodyguard surface prior to applying paint coatings.

Bodyguard painting know-how

Nail holes: if nails are countersunk, seal exposed wood with Bodyguard End Seal then fill nail holes with an exterior grade wood filler, then spot prime and undercoat. In temperatures less than 40°F use cold weather caulking sealants.

Remove all soft and chalky paint, dirt etc, and sand to a smooth even finish.

Apply two full coats of premium quality exterior acrylic house paint as per manufacturer’s instructions. For best results allow 24 hours between coats.

Moisture uptake before installation

Kiln-dried radiata pine wood is hydroscopic. It will absorb moisture in a damp environment and release it in a dry environment. If wood absorbs moisture, some dimensional swelling may occur. This will disappear when the wood returns to its original moisture content.

Primers provide limited protection against moisture uptake so it is essential that Bodyguard products are kept dry and stored in a dry environment away from damp ground, until installed.

During the installation process all exposed unprimed surfaces resulting from cut ends, miters, notching, boring, punched nail holes or similar, should be sealed with Bodyguard End Seal. Then painted with a suitable oil-based or acrylic premium exterior wood primer.

If paint coatings are applied to primed wood in which moisture-related dimensional swelling has occurred, then the process of moisture release is slowed considerably.

Shrinkage lines will occur as the wood returns to its equilibrium moisture content and original machined dimensions. To prevent this, ensure the wood is dry and at original machined dimensions before applying paint coatings. This applies to all products, expressly sidings.

Moisture uptake after installation

Application of the recommended painting specification will provide protection against moisture uptake minimizing dimensional change.

The primer will not protect against moisture uptake when exposed to continued rain or extreme weather. Under these conditions temporary dimensional swelling may occur.

It is essential that if swelling is evident, the product should be given time to dry out and return to its equilibrium moisture content and manufactured dimensions before application of any final coating system.

Resin bleed

Wood is a natural product and resin is a natural constituent of the pine species. Resin bleed is rare, but most likely to occur in hot sheltered conditions, or where the product has been painted a dark color.

Adherence to the above painting specification will assist in minimizing the potential for resin bleed. It is also recommended that the product is not painted in dark colors or high gloss finishes.